Paint additives can be divided into oil-based paint additives and water-based paint additives.

In response to the increasing global attention to environmental protection, the development of water-based paint additives has made a leap forward. There are more and more new environmentally friendly additives, and their applications are becoming more and more extensive. It is the mainstream direction of the future development of paint additives.

Relatively speaking, the problems of water-based coatings in construction are much more complicated than those of solvent-based coatings. Many complex problems such as shrinkage, blistering, floating color and other drawbacks are more likely to occur in water-based coating systems, while solvent-based coatings are relatively mild. A large reason for this difference is that the surface tension of water and solvents is quite different, so different results will inevitably occur under the same construction conditions.

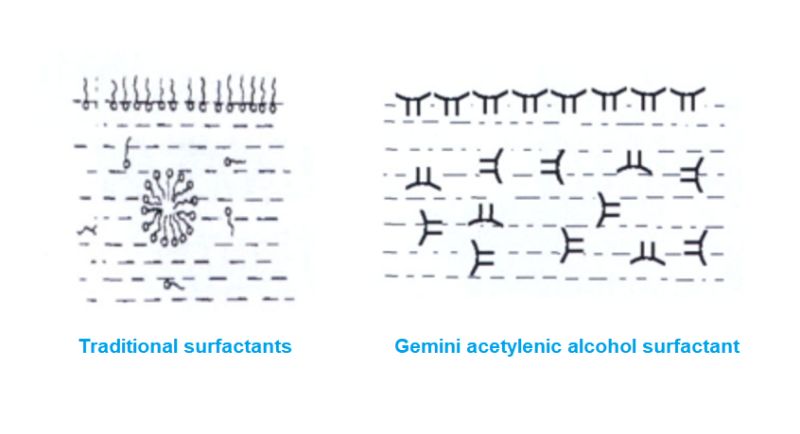

Traditional surfactants can solve the wetting of the substrate, but at the same time, these surfactants are also good at generating foam. After the foam is generated, only powerful defoamers can be introduced, usually silicone products, and the introduction of these defoamers can easily cause surface defects, and so on. Surfactants with special structures, such as surfactants with two hydrophilic groups and two lipophilic groups and two amphiphilic groups symmetrically connected, can solve the problem and eliminate the generation of foam from the source of foam. The structural characteristics of the new acetylene alcohol multifunctional surfactant and the comparative analysis with traditional surfactants show the application advantages of acetylene alcohol multifunctional surfactants in water-based coatings.

As we all know, traditional surfactants have only one hydrophilic group and one lipophilic group (matchstick type), which can provide excellent surface tension under static conditions. Once it is sprayed or coated at high speed, the surfactant effect is basically lost. The acetylene alcohol multifunctional surfactant has two hydrophilic groups and two lipophilic groups, and the two amphiphilic groups are symmetrically connected. Its interfacial activity is much higher than that of traditional surfactants. The size of the surface tension is directly related to the wetting degree of the aqueous system on a certain substrate. Generally, the smaller the surface tension, the better the wetting effect of the substrate, otherwise the wetting effect is worse. In addition, acetylene alcohol surfactants are mostly non-ionic surfactants, and the charge stabilizing factor does not exist; low surface viscosity, reducing foam stability; the hydrophilic group is relatively small, and microbubbles are easy to aggregate into large bubbles and break bubbles, etc.

Wuhan Bolachem New Material Co., LTD provides acetylene glycol ether wetting agents. PT-420/PT-440/PT-465/PT-2502 are typical Gemini non-ionic surfactants with excellent wetting and defoaming properties. They can effectively reduce the surface tension of water-based systems, especially the dynamic surface tension. It is widely used in water-based coatings, water-based adhesives, water-based inks and other industries. It can effectively wet, effectively reduce surface tension and prevent shrinkage.

The acetylene alcohol substrate wetting agent produced by our company can effectively improve the substrate wetting problem on waterborne systems.

1. Excellent static and dynamic surface tension.

It can still wet the substrate surface well under high-speed printing, brushing, spraying and other high-speed movements.

Compared with silicone products, the dynamic surface tension is significantly lower.

2. Excellent defoaming and anti-foaming effect

3. Low water sensitivity. Compared with traditional surfactants, the unique gemini structure of acetylene alcohol products determines its water resistance.

4. Won't form micelles, good storage stability.

5. Good thermal stability, good acid-base stability.

Applicable fields:

Coatings: water-based industrial paint, wood paint, metal paint, container paint, etc.;

Inks: varnish, fountain solution, inkjet (thermal, piezoelectric), gravure printing;

Adhesives: pressure-sensitive adhesives, pesticide spraying, etc.

Photovoltaic cutting fluids

Semiconductor front-end processing, etc.

Product | Substitute of | Chemical Composition |

PT-104 | Surfynol 104 | Acetylene diols |

PT-420 | Surfynol 420 | Ethoxylated acetylenic diols |

PT-440 | Surfynol 440 | Ethoxylated acetylenic diols |

PT-465 | Surfynol 465 | Ethoxylated acetylenic diols |

PT-2502 | Surfynol 2502 | Ethoxylated propoxylated acetylenic diols |

PT-110 Solid | Surfynol DF-110 | 2,5,8,11-Tetramethyldodec-6-yne-5,8-diol |

PT-640 | Dynol 604 | 2,5,8,11-Tetramethyl-6-dodecyn-5,8-diol ethoxylate |

PT-670 | Dynol 607 | 2,5,8,11-Tetramethyl-6-dodecyn-5,8-diol ethoxylate |