As a company currently engaged in the research and development of mainstream sedimentation agents in China, our company has successfully developed and produced PT-77 and PT-WT, two mainstream sedimentation agents on the market. At the same time, new corrosion challenges and industry pain points have been gradually discovered in the process of in-depth production and use of metalworking fluids.

In the process of metal cutting, grinding, stamping and other processing, cutting fluid, as a key process medium, undertakes multiple functions such as cooling, lubrication, rust prevention and cleaning. However, the long-term use of chlorine-containing additives in traditional cutting fluids has brought about corrosion risks that cannot be ignored. Chloride ions (Cl⁻) will destroy the passivation film on the metal surface, causing pitting, stress corrosion cracking (SCC) and shortened equipment life, which directly threatens processing accuracy, workpiece quality and equipment stability.

How to solve the problem of chloride ion corrosion without sacrificing the sedimentation performance of the processing fluid? PT-77F chlorine-free sedimentation agent was born out of demand, redefining the anti-corrosion standards of metalworking fluids with innovative technology!

PT-77F core advantages: The product does not contain chlorine, caters to the market demand for high-end chlorine-free formulas, and comprehensively breaks through the bottleneck of corrosion.

1. Zero chlorine addition, root cause of corrosion risk PT-77 uses an innovative structure to completely abandon traditional chloride sedimentation agents and cut off the introduction of chloride ions from the source of the formula. Significantly reduce the probability of contact between metal and corrosion factors, and completely avoid pitting, crevice corrosion and stress corrosion cracking caused by chloride ions.

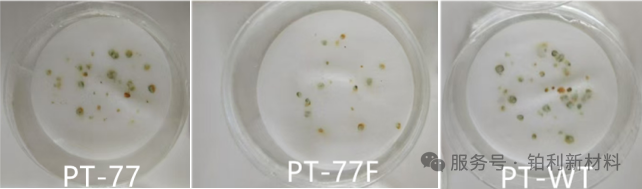

2. Promote the rapid and fine separation of particles, inhibit the reproduction of microorganisms, and accelerate the sedimentation of suspended matter in water (including metal powder, glass powder, and ceramic powder). The sedimentation effect is excellent. The comparison effect with the mainstream sedimentation agent in China is shown in the figure below:

3. Long-term corrosion protection, compatible with a variety of processing environments.

High temperature and high pressure resistance: It remains stable under high temperature and high pressure conditions, and is suitable for harsh scenes such as high-speed cutting and deep hole processing.

Broad spectrum applicability: Compatible with a variety of metal materials such as cast iron, aluminum alloy, stainless steel, titanium alloy, and non-metallic materials such as glass and ceramics, meeting the diversified needs of industries such as automobiles, aerospace, and precision molds.

(The above picture shows the metal corrosion comparison test of three kinds of sedimentation agents)

4. Environmentally friendly and safe, helping green production Non-toxic and harmless: does not contain heavy metals and controlled harmful substances (such as boron and nitrite), ensuring the health of operators. Excellent biodegradability: reduces waste liquid treatment costs and helps companies achieve sustainable development goals.

PT-77F can be used in concentrated processing fluids and can also be used in diluted processing fluids.

Fully synthetic processing fluid, recommended dosage 0.1-0.5%, can achieve a good sedimentation effect.

PT-77F——Chlorine-free technology, guarding metal every moment!